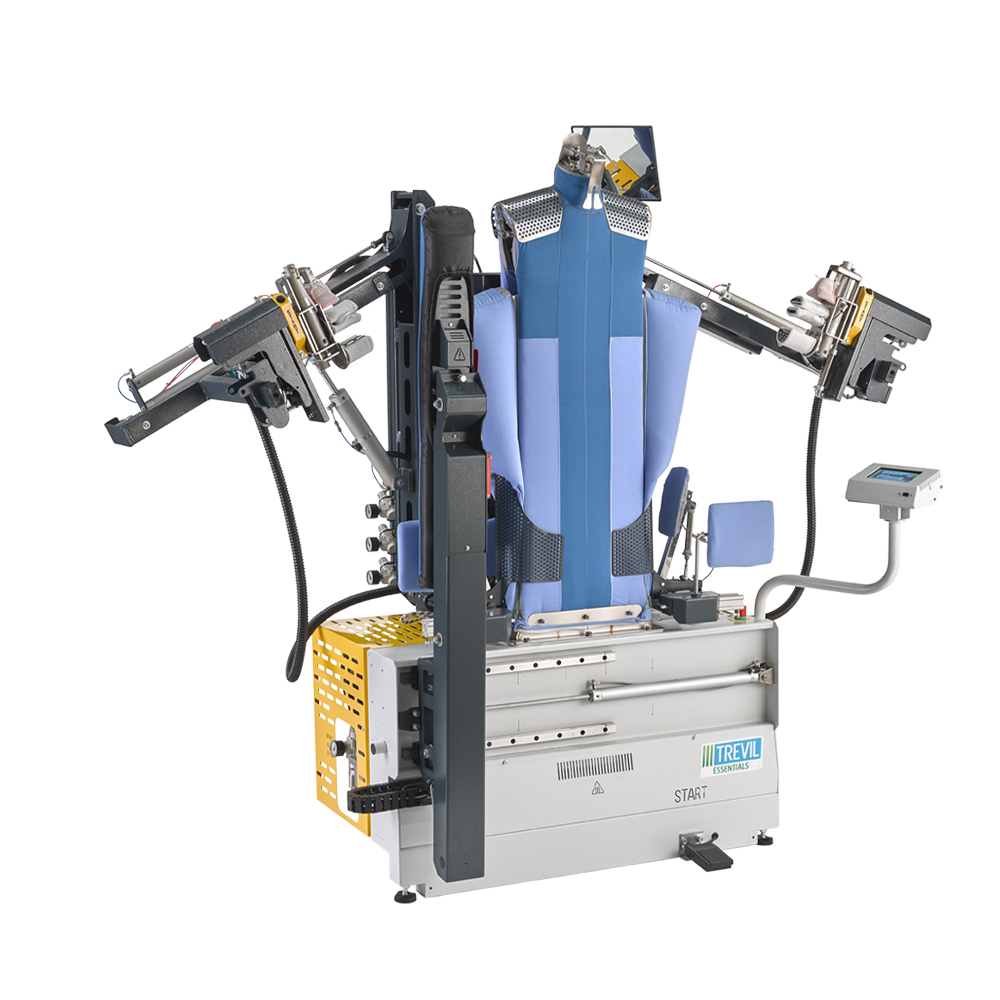

TREVISTAR ESSENTIALS

TREVISTAR ESSENTIALS

value for money shirt finisher, extremely compact.

Product code: 5295

Units for finishing at least 100 shirts per day

Shirt finisher that is able to process 35 shirts/hour. The ideal choice for an inexpensive automation of shirt finishing.

The machine is extremely compact.

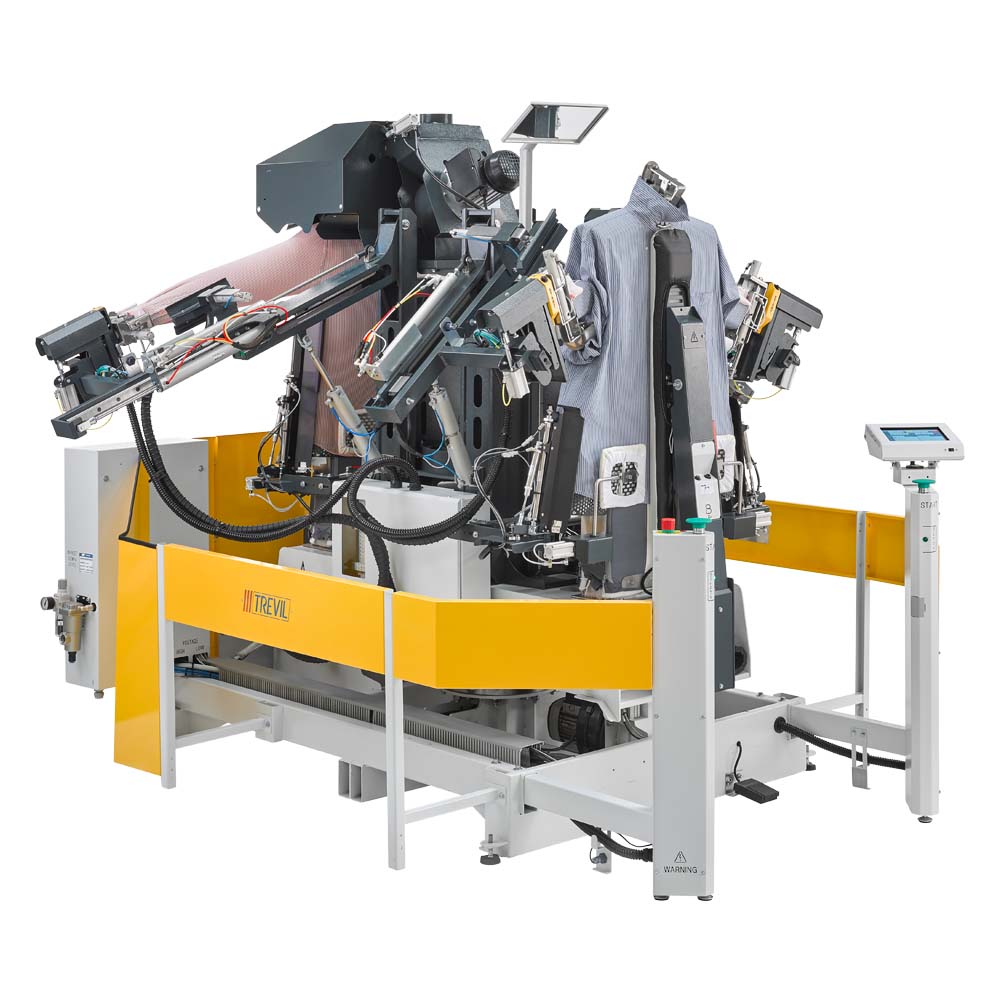

The movement of sleeve clamps is studied to keep the cuffs aligned to the shoulders.

All machine movements are pneumatic, controlled electronically and do not require manual movements.

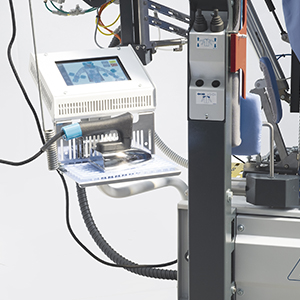

The TreviTouch touch screen makes using the machine very easy. The Smart interface allows to control all the movements in a very simple and intuitive way.

The console can be mounted on the left or on the right side of the machine, to fit in different store layouts.

MAIN FEATURES

All adjustments are just a tap away thanks to the Smart interface. As a result of a design targeted to ergonomics design, the operator can work comfortably, avoiding unnecessary movements. The screen is highly responsive, thus allowing accurate control of movements and the possibility to adjust the shirt position in real time.

5-clamp vertical tensioning system

The tensioning carriage is equipped with five clamps to guarantee an even finish of the hem.

The rear clamp holds the shirt’s tail, two side clamps tension the side seams, and to front paddles avoid horizontal lines.

One pedal operation

No waste of time looking for controls. The operator can focus on the dressing sequence with no distractions.

Pneumatic collar clamp

The shape of the collar clamp is made to make it easy to slip closed garments on the form, such as polo shirts.

Heated front clamp

The front clamp presses the front placket without damaging the buttons. The temperature setting is protected against accidental change.

PNEUMATIC ADJUSTMENT OF THE SLEEVES ANGLE

The angle between the sleeves and the body can be pneumatically adjusted via the graphic interface.

Pneumatic adjustment of shoulders width

Convenient buttons on the touchscreen allow to adjust the width of shoulder expanders, thus providing a wrinkle-free finish of the armhole.

Easy maintenance & troubleshooting

- conveniente spyholes allow to check the status of pneumatic valves;

- pop-up error or maintenance messages on the console;

- integrated diagnostics module for easy troubleshooting.

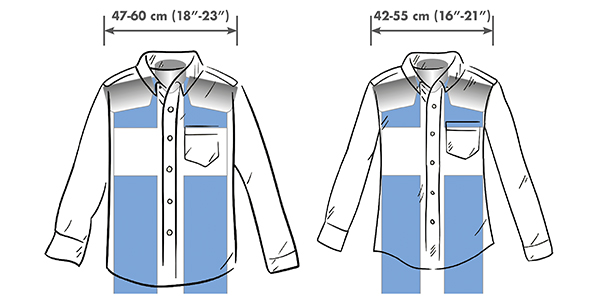

Two sizes of form available

A standard size for men’s shirts and a narrow buck for tapered shirts and ladies’ blouses.

Extremely compact

Only 0,8 sqm of floor space occupancy.

Repositionable console

The console can be positioned on the right or left side of the machine cabinet, according to the position of the cuff and collar press.

OPTIONS

Short sleeve clamps

Touch-up iron (F015) (F015)

Accurate and lightweight. The standard choice for wet shirts.

Collar cone

TECHNICAL SPECIFICATIONS

5295 |

|

|---|---|

| Description | Blowing shirt unit |

| Electrical requirements | 400V 3N 50Hz 220V 3 60Hz |

| Total power | 4 kW |

| Blowing power | 2,2 kW 3 HP |

| Suction power | 0,35 kW 0,5 HP |

| Front clamp | 1000 W |

| Steam consumption | 35 kg/h 77 lbs/h |

| Air consumption | 20 Nl/cycle 0,71 cfm |

| Steam pressure | 8 bar 116 PSI |

| Air pressure | 600 – 700 kPa 87-100 PSI |

| Footprint | 1120 x 805 mm 44″ x 33″ |

| Dimensions | 2880 x 980 x 1700 mm 113″ x 39″ x 67″ |

| Net weight | 310 kg 683 lbs |